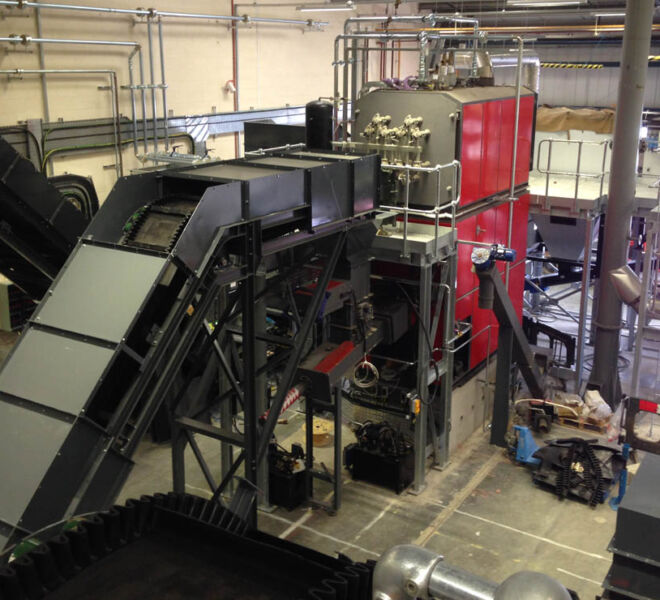

Heavy precision welding & fabrication to exacting standards that are both formidable and unique within the UK

Wright Engineering employ time served boilermakers, platers and welders, who have received all the necessary training and certification, to produce the fabricated items to the exacting standards that our customers rightly demand. The requirement for coding of welders for specific fabrication work, weld inspection and the carrying out of non-destructive testing to meet design requirements, is routinely carried out by our experienced staff.

The experience of the Fabrication Team with heavy precision fabrications is formidable and unique within the UK. The majority of the team have worked together for more than 35 years and their experience is key to the continued success of Wright Engineering. Wright Engineering, providing high quality fabrications to discerning clients since 1986.

Production Facilities

Wright Engineering’s production facilities provide the very latest manufacturing technology for fast-flow production with more traditional fabrication skills. These capabilities allow us to offer varied items, from mass produced components to more complex bespoke fabrication projects. Our two purpose built facilities at Worksop spanning 1250m2 allied with our third facility at Harworth covering almost 2000m2 house the necessary equipment to cut, bend, roll, manoeuvre and weld steel in a fast and efficient manner.

Surface treatment of fabrications and machined components comprises of Shotblasting and Painting. This is carried out in a dedicated adjacent shop allowing the full manufacturing process to be completed under the careful management of our quality policies.

Quality Assurance

The fabrication workshops operate fully within the ISO:9001 structure that we have developed to ensure that the traceability, quality checks, dimensional accuracy and finish are controlled and monitored throughout the manufacturing process. Wright Engineering are accredited to Execution Class 3 (EXC3), this certification demonstrates that Wright Engineering have the requisite Factory Production Control (FPC) system which ensures full life-cycle traceability, evidence of which will gladly be provided upon request.

This verifies compliance with the detailed requirements of BS EN 1090:2-2008 and EN ISO 3834:2 & 3-2005. This enables Wright Engineering to supply fabrications that are correct to the client’s requirements first time, on time.

![]()

For more information and enquiries on any of our services listed, please contact Wright Engineering directly. A member of staff is on hand to discuss and answer any questions you may have…

Wright Engineering U.K. Head Office & Works:

Carlton Forest, Red Lane, Blyth Road, Worksop, Nottinghamshire, S81 8BP, United Kingdom

Products

Wright Engineering’s diverse products range spans the materials handling and processing sectors…

Steelwork

Conveyor Systems

Silos, Hoppers & Vessels

Control / Operator Cabins

Bespoke Machinery

Spares & Maintenance

WDE Rock Breakers

Contractors Tools

Demolition Tools

SFH Electro Magnetic Feeders

DD Electro Mechanical Feeders

Vibrating Conveyors

Tube Conveyors

Grisly Screen Feeders

Hoppers & Ancillary Components

Sectors

Our continued success has seen expansion into sectors that play to the strengths of our highly experienced team…

Showcasing the many projects we deliver satisfying time, budget and functional requirements that would otherwise go unseen by anyone other than end users. Please explore our extensive portfolio…