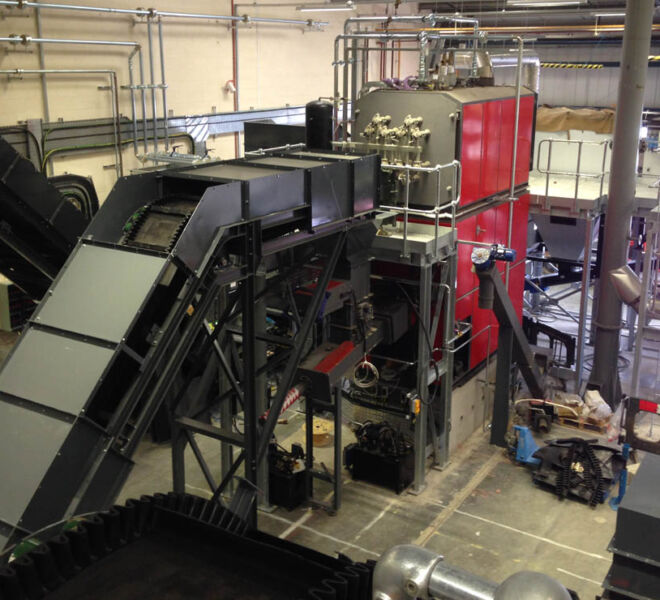

In-house design and engineering resources to transform client requirements into detailed solutions

Our experienced design engineers are well versed in performing site surveys and 3D scans enabling them to produce detailed layouts of existing equipment and buildings, thus providing a sound foundation for modifications or new project/process requirements to be accommodated. The design department at Wright Engineering consists of highly skilled and motivated professional mechanical and structural engineers with specialist knowledge of materials handling, process engineering and structural steelwork design. Our wealth of experience in the industry enables us to generate bespoke solutions that deliver the highest levels of efficiency and performance.

Design Process

The design process offers our clients innovative concepts and solutions. At project inception, we are able to offer ‘value engineering’ through the close guidance of our principal and senior design engineers, and with the assistance of the latest 2D and 3D computer aided design software, are able to transform ideas into working solutions.

![]()

![]()

DESIGN EXPERIENCE

We have found by experience that getting our customers to fully understand the solutions being proposed leads to a more focused final solution. Our engineers make sure that the initial layout drawings fully illustrate the solutions enabling customer feedback and detailed requirements to be incorporated at an early stage of the project.

![]()

IN-HOUSE CAPABILITIES

We have the manpower and facilities to detail all our designs so that manufacturing and procurement can be undertaken. Wright Engineering has a policy of management control during all phases of a project. Our design engineers provide an unbroken link between the client and the manufacture of the equipment, ensuring that the required high quality is maintained.

![]()

REGULATION REQUIREMENTS

Wright Engineering design engineers are fully conversant with the requirements of the Construction (Design and Management) Regulations.

The requirements on the designers that these regulations have enacted with regard to the installation of the equipment and the subsequent safe operation and maintenance of the installed plant are fully understood.

We undertake all Design Risk Assessments and the provision of these to the CDM Coordinator, and all the other design paper work is organised as a matter of course.

![]()

For more information and enquiries on any of our services listed, please contact Wright Engineering directly. A member of staff is on hand to discuss and answer any questions you may have…

Wright Engineering U.K. Head Office & Works:

Carlton Forest, Red Lane, Blyth Road, Worksop, Nottinghamshire, S81 8BP, United Kingdom

Products

Wright Engineering’s diverse products range spans the materials handling and processing sectors…

Steelwork

Conveyor Systems

Silos, Hoppers & Vessels

Control / Operator Cabins

Bespoke Machinery

Spares & Maintenance

WDE Rock Breakers

Contractors Tools

Demolition Tools

SFH Electro Magnetic Feeders

DD Electro Mechanical Feeders

Vibrating Conveyors

Tube Conveyors

Grisly Screen Feeders

Hoppers & Ancillary Components

Sectors

Our continued success has seen expansion into sectors that play to the strengths of our highly experienced team…

Showcasing the many projects we deliver satisfying time, budget and functional requirements that would otherwise go unseen by anyone other than end users. Please explore our extensive portfolio…