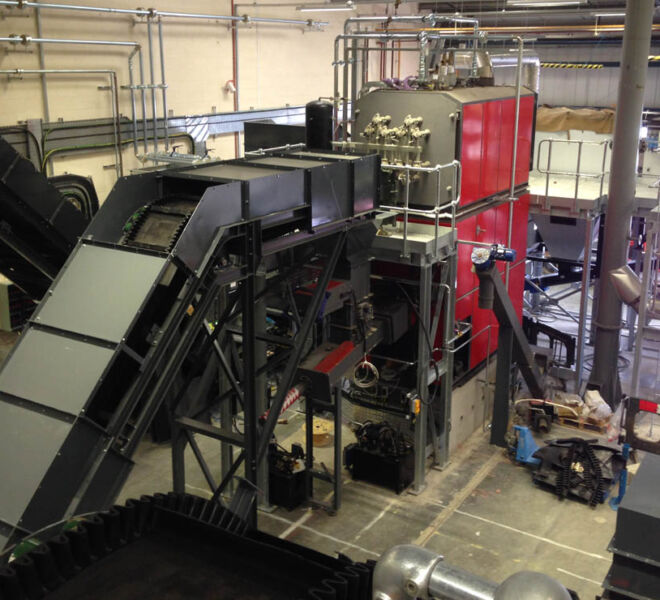

SFH Electro Magnetic Feeders for Accurate & Controlled Bulk Material Extraction

SFH Electro Magnetic Feeders have a rugged and robust design. When combined with our control panel they offer full flow speed control from 0-100% of available throughput. Our pans can be fabricated in a range of materials, including hi-quality carbon steel, stainless steel 304 & 316, with options for a variety of easily replaceable liner plate materials – including hi quality carbon steel, stainless steel, AR400 plate and chrome carbide weld overlaid plate. Our SFH Electro Magnetic Feeders are ideal for heavy duty applications and are available with throughputs of less than 1tph right up to (and beyond) 1100tph (based on 1600kg/m³ bulk density).

Incorporating years of experience in the field of Electro Vibrating Feeders, we have put vibration to work at new levels of improved efficiency. Utilising Natural Frequency to maximum advantage, the unique Super Feeder design gives you more feeding capacity at lower costs per conveyed ton.

What gives Locker Super Feeders this Performance Plus?

The heart of every Vibrating Feeder is its Power Unit. The new Locker Super Power, Ultra-Efficient, High Quality, Vibrator Power Unit, specially developed and produced by Locker gives each Feeder that increased capacity performance. In addition to good design, the efficiency, low power consumption, ease of control and quiet operation of the Locker Super Feeder depends on the timing and tuning of the vibrator.

The SFH Electro Magnetic Feeders are optimised through the Locker precision tuning and timing of the special vibrator bars, relative to the total vibrating mass. This gives you the highest efficiency ratio, relative to the Natural Mechanical Frequency of the unit.

Once the feeder has been correctly tuned, due to the low stresses placed on the vibrating bars and given correct scheduled maintenance, Locker SFH Electro Magnetic Feeders are proven to give decades of reliable service – we regularly encounter feeders in excess of 40 years old which are still in daily use.

Advantages of the Locker SFH Electro Magnetic Feeders…

- High Capacity – Single Power Unit Designs up to 1100TPU / Multi Power Units in excess of 1100 TPU (based on average bulk density 1600 Tm³).

- Heavy Duty, Reliable and Robust.

- Local or Remote Control options.

- Suspended or Foot Mounted.

- Fully Enclosed / Dust Sealed option available.

- Low Running Costs and virtually Maintenance Free.

- No Rotating Parts / Lubrication Free.

- Quiet Operation.

- Withstands Head Loads.

- Infinitely Variable Control.

- Operation Unaffected by No Load Condition.

Various pan configurations…

- Vee – to centralise product.

- Flat – for equal spread.

- Rounded – for high tonnage.

Steelwork

Conveyor Systems

Silos, Hoppers & Vessels

Control / Operator Cabins

Bespoke Machinery

Spares & Maintenance

WDE Rock Breakers

Contractors Tools

Demolition Tools

SFH Electro Magnetic Feeders

DD Electro Mechanical Feeders

Vibrating Conveyors

Tube Conveyors

Grisly Screen Feeders

Hoppers & Ancillary Components

![]()

For more information and enquiries on any of our products listed, please contact Wright Engineering directly. A member of staff is on hand to discuss and answer any questions you may have…

Wright Engineering U.K. Head Office & Works:

Carlton Forest, Red Lane, Blyth Road, Worksop, Nottinghamshire, S81 8BP, United Kingdom

Services

An unrivalled reputation for the design, manufacture, installation & commissioning of innovative engineering solutions…

Sectors

Our continued success has seen expansion into sectors that play to the strengths of our highly experienced team…

Showcasing the many projects we deliver satisfying time, budget and functional requirements that would otherwise go unseen by anyone other than end users. Please explore our extensive portfolio…