Our trained workforce provide a wide range of Industrial Rope Access services

Rope access is a system of work positioning, utilising skills and equipment developed from the climbing and caving world. Rope access is now seen by many companies and the HSE as a viable alternative to scaffolding and other more traditional methods of access. With a skilled and reputable workforce, we offer a wide range of Industrial Rope Access services. All our operatives are accompanied by a Level 3 supervisor on all projects.

We provide a full Risk Assessment and Method Statement for every rope access project we embark on, all of our operations conform to ISO 22846 – the code of practice for use of Rope Access for industrial purposes. We also follow the IRATA International Code of Practice.

Our specialist teams are empowered, productive and reliable to ensure that they complete tasks as simply and cost effectively as possible. We are quick to deploy enabling short notice mobilisation for emergency, planned and shutdown projects.

Advantages of Rope Access

- Rapid assembly and disassembly mean less disruption to your own business.

- Systems can easily be removed at the end of a shift providing less of a security risk to your premises.

- Single contact point for the client. Rope access technicians can set up the access system and also carry out the work.

- Rope access can generate real financial savings compared to more traditional methods as it is less invasive and has an excellent safety record.

![]()

SAFETY & QUALIFICATIONS

- All our employees are independently trained and assessed.

- All our supervisors are qualified and first aid trained.

- All our employees are IPAF trained and assessed.

- All personnel are holders of CCNSG cards.

- Our confined space team are all independently trained and assessed including the use of breathing apparatus.

- Our Fall prevention team are all independently trained and assessed and are authorised installers of fall arrest systems.

![]()

WE CAN OFFER

- Construction & Installation.

- Repairs & Maintenance.

- Inspections & Surveys.

- Safety & Rescue.

![]()

SCOPE SAMPLES

- Drop surveys.

- End of construction clean downs.

- EFW maintenance clean downs.

- NDT & structural inspection.

- Bridge refurbishment.

- Safety / asset condition inspections.

- Rockfall prevention systems.

- Surface Preparation & Protective Coatings.

![]()

For more information and enquiries on any of our services listed, please contact Wright Engineering directly. A member of staff is on hand to discuss and answer any questions you may have…

Wright Engineering U.K. Head Office & Works:

Carlton Forest, Red Lane, Blyth Road, Worksop, Nottinghamshire, S81 8BP, United Kingdom

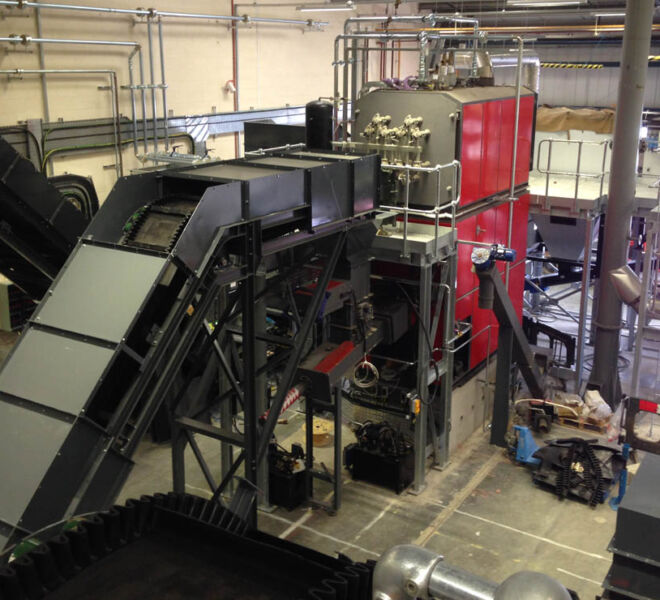

Products

Wright Engineering’s diverse products range spans the materials handling and processing sectors…

Steelwork

Conveyor Systems

Silos, Hoppers & Vessels

Control / Operator Cabins

Bespoke Machinery

Spares & Maintenance

WDE Rock Breakers

Contractors Tools

Demolition Tools

SFH Electro Magnetic Feeders

DD Electro Mechanical Feeders

Vibrating Conveyors

Tube Conveyors

Grisly Screen Feeders

Hoppers & Ancillary Components

Sectors

Our continued success has seen expansion into sectors that play to the strengths of our highly experienced team…

Showcasing the many projects we deliver satisfying time, budget and functional requirements that would otherwise go unseen by anyone other than end users. Please explore our extensive portfolio…