Hope Construction Photo Gallery

PROJECT DETAILS

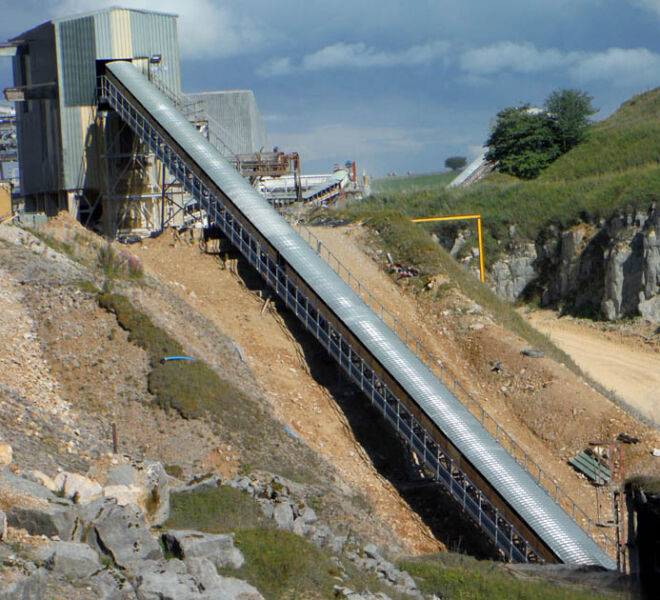

Hope Construction faced a significant operational hurdle with an ageing conveyor that was critical to their plant production. They approached us for a solution that would involve designing, supplying, and installing a replacement conveyor with minimal downtime. We rose to the challenge, successfully engineering a solution that allowed for a rapid replacement while keeping the plant’s productivity uninterrupted.

The Challenge

Minimising Downtime: The primary requirement was to keep the downtime to no more than 24 hours, a crucial factor for maintaining continuous plant operations.

Replacement of Ageing Conveyor: The existing conveyor was vital to the plant’s production, and its replacement needed to be handled without disrupting ongoing operations.

Our Approach

Innovative Engineering: We developed a civil package and designed a 94 m-long conveyor that could be installed with minimal interference to the existing system.

Strategic Installation: The plan allowed for almost the entire installation of the new conveyor to occur while keeping the existing conveyor operational.

Successful Execution

Adhering to Time Constraints: The 24-hour shutdown period was meticulously planned and successfully adhered to, ensuring that the plant’s production was minimally affected.

Project Achievement: This project stands out as one of our most significant achievements, demonstrating our capability to deliver complex solutions within stringent time constraints.

Conclusion

The conveyor replacement project for Hope Construction exemplifies our expertise in delivering engineering solutions that meet critical operational needs while adhering to tight schedules. Our ability to engineer and execute a project of this complexity within a 24-hour shutdown period highlights our commitment to providing efficient and innovative solutions to our clients.

Contact Wright Engineering